空气能 发布日期:2023-10-21 阅读次数:1058

1 Introduction

Due to energy shortage and environmental pollution, heat pump units are widely used in building heating, industrial heating, mate-rial drying, ventilation, and dehumidification because of their effi- cient, environment-friendly, and safe features [1]. In 2021, China’s National Energy Administration proposed to further reduce the proportion of coal consumption and vigorously pro- mote the use of heat pump technology for cooling and heating in the hot summer and cold winter areas [2].

When the climate is cold in winter and the heat pump unit is heating, frost will form on the finned surface of the outdoor finned coil evaporator when the temperature is below 0 O C and below the dew-point temperature of the outdoor air [3]. The frost will have an obvious impact on the operation of the heat pump unit [4], including: ‹ blocking the channels between the fins, increasing the airflow resistance and making the energy consumption of the fan increase; › increasing the thermal resistance of the heat exchanger, making the heat transmission performance of heat exchanger decline, and reducing heat transfer capacity; fi reduc- ing evaporating temperature, reducing energy efficiency ratio, and deteriorating the operating performance of heat pump units. Therefore, the frost problem has become a big obstacle to the pop- ularization and application of heat pump units, and the defrosting method is usually adopted to solve the problem in the operation of heat pump units [5]. However, there are still some problems in the operation of heat pump units, such as short defrosting cycles, heat supply interruption caused by frequent defrosting, and reduction of indoor comfort [6].

Delaying the frost formation can effectively prolong the defrosting cycle and improve the heating performance of the heat pump units. Research on delaying frost can be broadly divided into three aspects [7]: ‹ change the outdoor environmental parameters [8]. Changing the temperature, humidity, airspeed and other natural factors of the outdoor environment needs high requirements for equipment, space, and other conditions, which is difficult to fit in a large area; › change the finned characteristics [9–12], although in the early stage this way has a good effect of frost suppression, its ability of frost suppression gradually decreases with the increase of time and the thickness of frost layer, and there are certain limitations because the process of material preparation is complicated and it is difficult to mass- produce; fi use the external force [13], for example, the application of external magnetic field, electric field, ultrasonic, mechanical vibration, and other methods to delay the formation of frost, but the principle of its effect on frost is not clear at present, pending further research.

Delaying frosting is difficult to achieve, so increasing fin spac- ing to prolong the time for the frost layer to block the air channels, prolong the defrosting cycle, reduce the defrosting frequency, and improve heat pump heating or cooling capacity is an effective measure to take. People usually take different fin spacing of the air cooler according to the different temperatures of the cold stor- age: the fin spacing of 8mm is selected for the cold storage tem- perature from —25 O C to — 16 O C, 12mm is selected from —25 O C to —35 O C, and the fin spacing can even reach 16mm in the freez- ing room with high humidity. The increase in the fin spacing of the air cooler has a significant effect on prolonging the defrosting cycle of the cold storage, but it will also change the degree of strengthening of the heat transfer area of the finned coils air cooler, and the heat transfer performance of the whole air cooler will also be changed.

In 2018, Zhang et al. [14] found that the use of a larger fin pitch (3.2mm) is advantageous in ensuring a relatively steady heating1Corresponding author.

Contributed by the Heat Transfer Division of ASME for publication in the JOURNAL OF HEAT TRANSFER . Manuscript received September 22, 2021; final manuscript received April 30, 2022; published online June 7, 2022. Assoc. Editor: Milind A. Jog.

output, as a frosted finned tube heat exchanger with a smaller fin pitch (2mm) would experience a quicker drop in its heat transfer rate when its windward side was blocked by frost. In 2020, Liu et al. [15] found through numerical simulation that when the fin spacing is small, the heat transfer capacity and pressure drop of the heat exchanger are influenced by the spacing; as the fin spac- ing increases, the influence of the spacing on the heat transfer capacity and pressure drop decreases gradually, but too small (1mm) or too large (9mm) fin spacing will limit the comprehen- sive performance. In the actual operation process of the heat pump, frost mainly occurs in the front row of the windward finned tube bundle, and the frost mass of the back row is less due to the decrease in air humidity. Therefore, the variable pitch finned coil heat exchanger (VPFCHX) can be applied to the air source heat pump. The so-called VPFCHX means that the fin pitch of the front row of the finned coils is increased appropriately, and the fin pitch of the middle and back rows remains the same or is reduced

appropriately, which can delay the blocking effect of the frost

layer on the front row of fins, to prolong the defrosting cycle and reduce the energy consumption for defrosting, maintaining the

heat transfer area and heat transfer capacity of the whole heat

exchanger [16]. In 2005, Rao et al. [17] found that the design of variable pitch (VP) (4.0mm for the first two rows and 2.0mm for the last three rows) is an effective means to improve the evapora- tor under frosting conditions by establishing a mathematical model, which can effectively prolong the defrosting cycle and increase the heat transfer per unit volume and per unit resistance of the evaporator. In 2003, Lang et al. [18] built a mathematical model for calculation and analysis, and found that the adjustment of the fin spacing (16.0mm for the first three rows and 8.0mm for the last nine rows) of each row improved the uneven distribution of airflow resistance in each row and effectively improved the per- formance of the units. In 2014, Qin et al. [19] built a mathematical model for simulation calculations and found that the structure of VP (10.0mm for the first three rows and 5.0mm for the last three rows) can improve the utilization efficiency of heat transfer area and heat transfer performance.

At present, the performance of the VPFCHX under frosting conditions is mainly limited to numerical simulation, and the experimental research is few. In this paper, the experimental study of the three rows of VPFCHX and fixed pitch finned coil heat exchanger (FPFCHX) is carried out, and the frosting and heat transfer performance of VPFCHX under the frosting condition are compared, which provides a reference for the application of the three rows of VPFCHX in air source heat pump.

2、Experimental Finned Coil Heat Exchanger and Set-Up

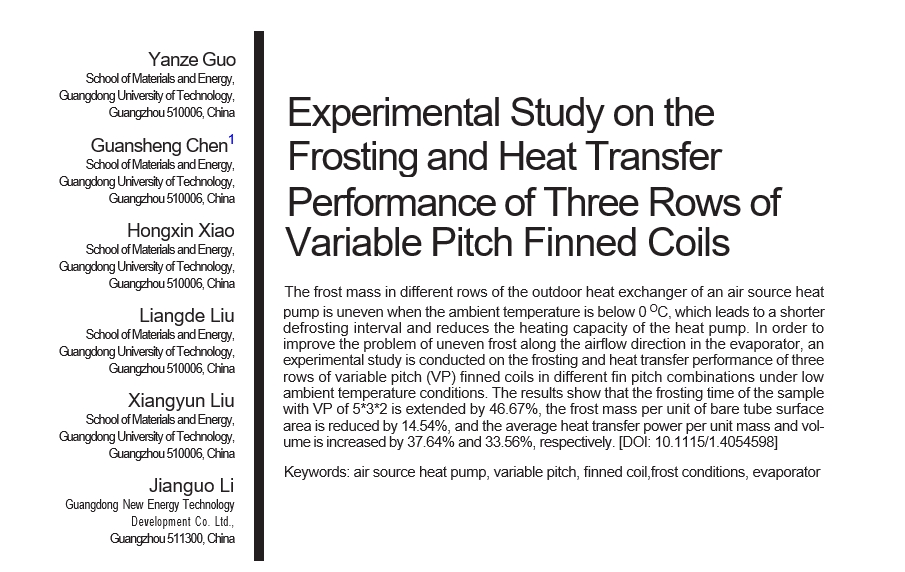

2.1Experimental Finned Coil Heat Exchanger. In order to better observe the formation of the heat exchanger frost layer and collect data, a visual experiment station was built and single row finned coils with fin spacing of 2mm, 3mm, 4mm, and 5mm were customized as shown in Fig. 1, and the parameters are shown in Table 1.

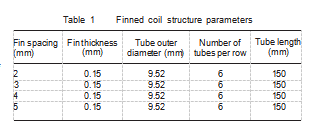

The selected FPFCHX and VPFCHX are three rows of corru- gated finned coil heat exchanger (FCHXs) connected by U-type

tubes. The structure is shown in Fig. 2, and the parameters of the three rows of heat exchangers are shown in Table 2.

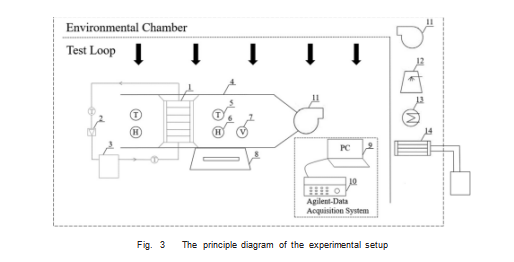

2.2 Experimental Set-Up. The schematics of the experimen- tal setup are shown in Fig. 3. As seen, the setup consisted of an environmental chamber and a test loop.

The experimental environment chamber is based on the multi- working condition Enthalpy Difference Laboratory of Guangdong New Energy Technology Development Co., Ltd., with an adjusta- ble temperature range of —45 O C to 45 O C, relative humidity of 30%–90%, and accuracy of 62%. The laboratory meets the test standard requirements of many national standard documents for heat pump units such as GB/T 25127.1-2010 and GB/T 25127.2-2010. Specific experimental thermal conditions can be maintained using a separate air conditioning system consisting of a fan (11), humidifier (12), heater (13), and cooler (14), as shown in Fig. 3.The test loop includes experimental FCHX (1), flow sensor (2), cryostat (3), duct (4), temperature sensor (5), relative humidity sensor (6), air flow sensor (7), electronic weighing scale (8), com- puter (9) and Agilent data collector (10), in which the flowmeter is an LZB-6 glass rotor flowmeter (from Jiangsu Province, China) with a measurement range of 0.1– 1L/min, and accuracy of 61.5%; the cryostat is a DC-2006S high-precision cryostat with a temperature control range of —20 to 100 O C and a coolant of 50% glycol-de-ionized water solution by volume; the relative humidity sensor is a JR900 laboratory grade standard version with a test humidity range of 10%RH—99%RH, and accuracy of 61%; the air flowmeter is T-DCI-F900-L-P with a measuring range of 0.15– 10m/s, and accuracy of 61%; the data acquisition instru-ment consists of a temperature measuring line TT-T-30 (made by Omega Company) with a T-type thermocouple, an Agilent 34972A and a computer terminal, and accuracy of 60.8%; the fan is an axial flow fan with a speed of 2800 r/min and a power of 60W.

There are nine measuring points in the experiment, which mea- sure the air inlet temperature, air inlet humidity, air outlet temper- ature, air outlet humidity, coolant solution inlet temperature, coolant solution outlet temperature, coolant solution flow, frost mass, and air velocity. The heat transfer ability and frost suppres- sion ability of VPFCHX and FPFCHX were explored and com- pared under the same low-temperature conditions.

2.3Experimental Procedure. The device is mainly divided into three systems: refrigeration, heat exchange, and data acquisi- tion. The coolant in the cryostat is cooled to —20 O C and enters from the inlet of the heat exchanger. After entering the heat

exchanger for heat exchange, the coolant from the outlet returns to the cryostat to complete the cycle; the air is sucked into the acrylic duct by the fan, and the convection between the air and the heat exchanger is strengthened; the solution inlet temperature, solution outlet temperature, air inlet temperature, air outlet tem- perature, and air velocity are measured every 1min and exported to the computer terminal by thermocouple and Agilent 34972A data acquisition instrument.

An electronic scale is used to measure the frost mass in the experiment, which can display the weight on the electronic dis- play screen in real-time. After putting the experimental equipment on the electronic scale, the number will be reset to zero, and the weight obtained is the increased frost mass. Every minute, the electronic weighing scale is placed under the acrylic duct to record the frost mass of the heat exchanger, the hygrometer records the humidity of the air inlet and outlet, and the glass rotameter measures the flow rate of the coolant solution, and the anemometer measures air velocity. Meanwhile, photographs are taken of the frost in the heat exchanger every 10min. When a large area of the fin is frosted and the mass growth is not obvious, the data collection and photoshooting of the refrigerant cycle are stopped and the experiment is ended.

3、Results and Discussion

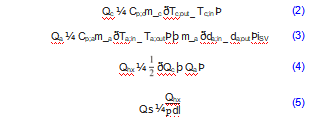

3.1 Data Processing. In the experiment, the frost density on the surface of the bare tube is the ratio of the frost mass to the surface area of the bare tube, and the calculation formula is as follows:

where m is frost mass, d is the diameter of the tube, and l is the tube length.

In the experiment, the heat transfer power of the heat exchanger takes the arithmetic mean value of the heat transfer power on the coolant side and the air side, and the calculation formula is as follows:

where Qc , Qa, Qhx , and QS are the heat transfer power of the cool- ant side, the heat transfer power of the air side, the heat exchanger power, and the heat transfer power of the bare tube surface, respectively. Ta;in andTa;out are the temperature of the coolant at the inlet and outlet of the heat exchanger, Tc;in andTc;out are the air temperature before and after flowing through the heat exchanger, respectively. Cp,a and Cp,c are specific heat capacities at the con- stant pressure of the coolant and air, m_c and m_a are the mass flow of the coolant and air, da;in and da;out is the moisture content of the air before and after flowing through the heat exchanger, respec- tively. iSV is the latent heat of sublimation for water.

The formula for calculating the heat transfer coefficient of the FCHX is calculated as

where h denotes the heat transfer coefficient; A denotes the heat transfer area.

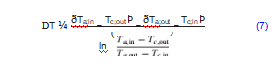

The logarithmic mean temperature difference DT is calculated as follows:

The formulae for heat transfer power per unit mass and heat trans- fer power per unit volume are defined as follows:

where QM and QV are the heat transfer power per unit mass and per unit volume of the heat exchanger, respectively, where Qhx is the average heat transfer power.

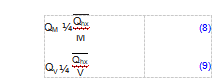

3.2 Frost Distribution and Growth. The time variations of frost growth and distribution of finned coils on the windward are shown in Fig. 4. The experiment ended when the channels were severely blocked by frost or the increase in mass was not obvious.

The experimental results show that sample 5 with FP takes the shortest time, only 60min, because the fin spacing between the first and second rows on the windward side was increased in sam- ple 4 with VP, the time for frost layer blocking was 66min, which was slightly longer than the sample 5 with FP. And sample 1, sample 2, and sample 3 with the largest fin spacing in the first row on the windward side take 93, 90, and 88min, respectively. Com- pared with samples 1–3, it can be found that when the fin spacing on the windward side is the same, the decrease of the fin spacing on the backside will also shorten the time used for clogging to a certain extent. Therefore, increasing the fin spacing on the wind- ward side can delay the formation of frost, thus inhibiting frost formation.

3.3Analysis of Frost Growth. Under frosting conditions, frost thickness is one of the major factors influencing heat transfer performance, because frost increases both thermal resistance and pressure drop in a heat exchanger.

It can be seen from Fig. 4 that there is an obvious difference in the time and rate of frost formation between VPFCHX and FPFCHX. The frost blocking time and frost mass are proportional to the fin spacing of tube rows on the windward side, that is, when increasing the fin spacing of tube rows on the windward side, the time needed for channel blocking and frost mass will also increase. The time from the start of the experiment to the frost blocking of the channel in the sample 5 with FP was about60min. Compared with the sample 5 with FP, the blocking time of samples 1–4 was prolonged by 33, 30, 28, and 6min, respec- tively. Therefore, increasing the fin spacing of tube rows on the windward side has a significant advantage in inhibiting frost.

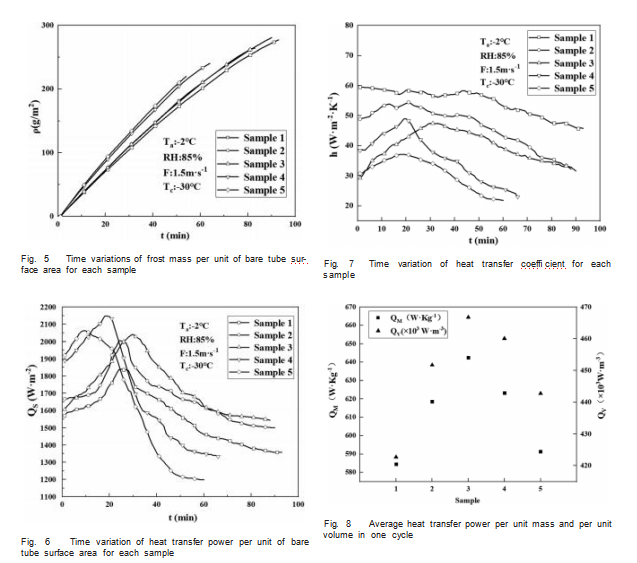

3.3.1Frost Mass Per Unit of Bare Tube Surface Area. Based on Eq. (1), the time variations of frost mass per unit of bare tube surface area for samples 1–5 using experimental measurements are shown in Fig. 5.As can be seen from Table 2, as the outer diameter and length of tubes are the same, the bare tube surface area of each sample is the same. The rate of frost formation all gradually decreases with increasing time. Because the fin spacing of the first and the second rows on the windward side of the VPFCHX are larger, the frost can be accommodated relatively more. The frosting rate of sample 5 with FP was the fastest, and the frost mass per unit of bare tube surface area was 170.1g/m2 at 50min, which was lower than sam- ples 1–4 with VP. The frost mass per unit of bare tube surface area of samples 1–4 was 178.4g/m2, 176.6g/m2, 201.0g/m2, and 206.6g/m2, respectively. At 55min, compared with sample 3 and sample 4, which only changed the fin spacing between the first row of tube rows on the windward side of the heat exchanger, the frost mass per unit of bare tube surface area were 192.0g/m2 and 217.4g/m2, respectively; compared with sample 2 and sample 3, which only changed the fin spacing of the second tube row on the windward side of the heat exchanger, the frost mass per unit of bare tube surface area were 193.9g/m2 and 192.2g/m2, respec- tively; compared with sample 1 and sample 2, which only changed the fin spacing of the third tube row on the windward side of the heat exchanger, the frost mass per unit of bare tube surface area were 184.9g/m2 and 193.9g/m2, respectively. It can be seen that compared to the sample with FP, the samples with VP all had a longer frosting time. And the frosting rate of the heat exchanger can be inhibited by changing the fin spacing of tube rows on the windward side, and the effect of changing the fin spacing of the first row is the most obvious.

3.3.2Heat Transfer Power Per Unit of Bare Tube Surface Area. Based on Eqs. (2) and (3), the heat transfer power per unit of bare tube surface area of solution and air can be calculated, and the error between the two data is less than 5%. Based on Eqs. (4) and (5), the time variation of heat transfer power per unit of bare tube surface area can be obtained as shown in Fig. 6. As can be seen from Table 2, as the outer diameter and length of tubes are the same, the bare tube surface area of each sample is the same.

At the beginning of frosting, the roughness of the surface is increased due to the ice crystals formed on the finned surface of each sample, so the heat transfer is enhanced. At the same time, the turbulence of air on the surface is increased due to the

formation of ice crystals, so the heat transfer is enhanced. How- ever, the data of the experiment show that the heat exchange of each sample decreases after reaching the peak value, because with the increase of time and the frost thickness, the outer heat resist- ance of the heat exchanger increases, the heat exchange perform- ance decreases significantly, and the heat transfer power per unit of bare tube surface area also shows a downward trend. Moreover, the increase in frost thickness reduces the airflow between the fins, which also leads to a decrease in heat transfer power. In the early stage of the experiment, the heat transfer power per unit of bare tube surface area of sample 5 with FP was higher than the samples with VP due to its the largest heat exchange area, but it dropped rapidly and was unstable in the later stage. Although the heat transfer power per unit of bare tube surface area of the sam- ples 1–4 with VP decreased in the later stage, it tended to be stable after falling to a certain value and the change was not obvious. Sample 1, sample 2, and sample 3 with the largest fin spacing on the windward side have less influence on the decrease of heat transfer power per unit of bare tube surface area in the later stage, and the heat transfer power can also be kept in a relatively stable range. In one cycle, the average heat transfer power of samples 1–5 were 1562.9W/m2, 1682.6W/m2, 1735.6W/m2, 1698.3W/m2 and 1631.9W/m2, respectively. Due to the reduction of too much heat exchange area, the heat transfer power per unit of bare tube surface area of sample 1 with VP is the smallest even if the fin spacing increases, and due to the increase of fin spacing, even if sample 5 with FP has the largest heat exchange area, the heat transfer power per unit of bare tube surface area is not high yet.

It can be seen that too large or too small fin spacing is disadvan- tageous to the increase of heat transfer power, so sample 3 was less affected by frost when maintaining considerable heat transfer power per unit of bare tube surface area.

3.3.3Heat Transfer Coefficient. Based on Eq. (6), the time variation of the heat transfer coefficient for each sample can be calculated, as shown in Fig. 7. By observing the change of the heat transfer coefficient for each sample, it is easier to see the laws and differences between VPFCHX and the FPFCHX: the change of the heat transfer coeffi- cient of each sample is similar to the heat transfer power, the heat transfer coefficient increases first and then decreases. The heat exchange area of samples 1–4 with VP is smaller than sample 5 with FP, but the heat transfer coefficient is higher than sample 5 with FP, and the heat transfer coefficient of sample 5 decreases rapidly in the middle and late stage. The heat transfer coefficient of sample 1, sample 2, and sample 3 with the largest fin spacing on the windward side is less affected by frosting in the later stage. Comparatively, the heat transfer coefficient of sample 1 decreases gradually and is less affected by frosting in the later stage. The intersection points of the heat transfer coefficient curves of sample

3 and sample 4 appeared at about 25min, because the heat exchange area of sample 4 is larger than sample 3 at the beginning of the experiment, so the heat transfer power and heat transfer coefficient are higher. But with the increase of frost thickness, the outer heat resistance of the heat exchanger increases, so the heat exchange performance decreases significantly, the heat transfer coefficient also decreases, and the increase of frost thickness reduces the airflow between the fins and the effective contact between the air and the fins, which also leads to the decrease of the heat transfer coefficient of sample 4.

It can be seen that properly increasing the fin spacing of tube rows on the windward side can delay the clogging effect of frost on the front fin, improve the heat transfer power, and increase the heat transfer coefficient and heat transfer efficiency.

3.4 Average Heat Transfer Power per Unit Mass and per Unit Volume. Based on Eqs. (7) and (8), the average heat transfer power per unit mass and per unit volume for each sample can be calculated as shown in Fig. 8. The lower the heat transfer power per unit mass and unit volume are, the less the unit consumes and the more compact it is. The reduction of heat exchange area of sample 1 and the reduction of fin spacing of sample 5 lead to the reduction of heat transfer power per unit mass and unit volume.

For sample 3, the influence of frost is reduced due to the increase in fin spacing of the first row on the windward side, and the decrease of the fin spacing of the back rows can increase the heat exchange area, to improve the heat transfer power per unit mass and unit volume. In one cycle, heat transfer power per unit mass and per unit volume of sample 3 is 642.44W/Kg and 466.74 x 103 W/m3, respectively, which are 37.64% and 33.56% higher than sample 5 with FP. It can be seen that sample 3 with VP has less material consumption and a more compact structure than sample 5 with FP.

4 Conclusion

The performance of the VPFCHX prototype compared to the performance of a conventional FP prototype at low temperature operating conditions, and the conclusions were as follows:

(1) The fin spacing on the windward side of the heat exchanger tube rows can effectively delay the formation of frost layer and blockage of the front row fins, prolong the defrosting cycle and reduce defrosting energy consumption. Com- pared to the sample 5 with FP, the frost mass per unit of bare tube surface area of samples 1–4 decreased by 17.69%, 13.64%, 14.54%, and 2.70%, respectively.

(2) Compared with sample 5 with FP, the average heat transfer power per unit of bare tube surface area of samples 1–4 is increased by —4.52%, 2.02%, 5.42%, and 3.92%,respectively.

(3) Sample 3 is superior to other samples, its heat transfer power per unit mass and unit volume are increased by 37.64% and 33.56% to those values of the sample 5 with FP, respectively, which can reduce the material consump- tion and the unit volume significantly.

Funding Data

O Guangzhou Science and Technology Program Key Projects

(Grant No. 201902010021; Funder ID: 10.13039/ 501100004000).

Nomenclature

A ¼ heat transfer area, m2

Cp ¼ specific heat at constant pressure, J/(kg.K) d ¼ tube outer diameter, mm

da ¼ air moisture content, kg/kg (dry air)

h ¼ heat transfer coefficient, W/(m2 .K)

iSV ¼ latent heat of sublimation, J/kg

l ¼ tube length, mm

m ¼ frost mass, g

m_ ¼ mass flow rate, kg/s

M ¼ mass of heat exchanger, kg

Q ¼ heat transfer power, W

QM ¼ heat transfer power per unit mass, W/kg

QS ¼ heat transfer power per unit of bare tube surface area, W/m2

QV ¼ heat transfer power per unit volume, W/m3 RH ¼ relative humidity

t ¼ time, s

T ¼ temperature, K

v ¼ wind speed, m/s

V ¼ volume of a heat exchanger, m3

Subscripts

a ¼ air

c ¼ coolant

hx ¼ heat exchanger

in ¼ inlet

out ¼ outlet

Greek Symbols

D ¼ relative error

p ¼ bare tube surface frost density, g/m2

Acronyms

FCHX ¼ finned coil heat exchanger

FP ¼ fixed pitch

FPFCHX ¼ fixed pitch finned coil heat exchanger

VP ¼ variable pitch

VPFCHX ¼ variable pitch finned coil heat exchanger

References

[1] Okbaz, A., Pınarba![]() ı, A., and Olcay, A. B., 2020, “Experimental Investigation of Effect of Different Tube Row-Numbers, Fin Pitches and Operating Condi- tions on Thermal and Hydraulic Performances of Louvered and Wavy Finned Heat Exchangers,” Int. J. Therm. Sci., 151, p. 106256.

ı, A., and Olcay, A. B., 2020, “Experimental Investigation of Effect of Different Tube Row-Numbers, Fin Pitches and Operating Condi- tions on Thermal and Hydraulic Performances of Louvered and Wavy Finned Heat Exchangers,” Int. J. Therm. Sci., 151, p. 106256.

[2] China’s National Energy Administration, 2021, “Adjust Measures to Local Conditions to do a Good Job of Renewable Energy Heating Work Notice,” Chi-na’s National Energy Administration, Beijing, China.

[3] Hayashi, Y., Aoki, A., Adachi, S., and Hori, K., 1977, “Study of Frost Proper- ties Correlating With Frost Formation Types,” ASME J. Heat Transfer-Trans.ASME, 99(2), pp. 239–245.

[4] Wang, W. Y., and Li, Y. Y., 2019, “Intermediate Pressure Optimization for Two-Stage Air-Source Heat Pump With Flash Tank Cycle Vapor Injection Via Extremum Seeking,” Appl. Energy, 238, pp. 612–626.

[5] Amer, M., and Wang, C. C., 2017, “Review of Defrosting Methods. Renewable and Sustainable,” Energy Rev., 73, pp. 53–74.

[6] Sourbron Maarten, G., and Nesrin, O., 2016, “Determination of Heat Transfer Characteristics of Solar Thermal Collectors as Heat Source for a Residential Heat Pump,” J. Sol. Energy Eng., 138(4), p. 041011.

[7] Wang, M., Zang, R. Q., Feng, H., Yu, C. Q., Wang, H., and Zhang, C. X., 2018, “Study on the Liquid Refrigerant Defrosting System and the Defrosting Rule,”J. Therm. Sci. Eng. Appl., 10(5), p. 051023.

[8] Jones, B. W., and Parker, J. D., 1975, “Frost Formation With Varying Environ- mental Parameters,” ASME J. Heat Transfer-Trans. ASME, 97(2), pp. 255–259.

[9] Lee, W.-J., Bae, K. J., and Kwon, O. K., 2020, “Effect of Hydrophobic Surfaces on Frost Retardation in Fin-Tube Heat Exchangers With Various Fin Pitches,” Appl. Therm. Eng., 176, p. 115424.

[10] Pu, L., Liu, R., Huang, H., Zhang, S. Q., Qi, Z. G., Xu, W. D., and Zhou, J., 2020, “Experimental Study of Cyclic Frosting and Defrosting on Micro-Chan- nel Heat Exchangers With Different Coatings,” Energy Build., 226, p. 110382.

[11] Lei, S. W., Song, M. J., Libor, P., and Shen, J., 2021, “A Numerical Study on Frosting and Its Early Stage Under Forced Convection Conditions With Surface and Environmental Factors Considered,” Sustainable Energy Technol. Assess., 45, p. 101202.

[12] Ho, J. C., Bin, L. J., Hyuk, L. S., Jungho, L., Mun, Y. S., and Kyoung, C. C., 2016, “Frosting Characteristics on Hydrophilic and Superhydropho- bic Copper Surfaces,” ASME J. Heat Transfer-Trans. ASME, 138(2), p. 020913.

[13] Martı粵nez-Fr![]() as, J., and Aceves, S. M., 1999, “Effects of Evaporator Frosting on the Performance of an Air-to-Air Heat Pump. Journal of Energy Resources Technology,” J. Energy Res. Technol., 121(1), pp. 60–65.

as, J., and Aceves, S. M., 1999, “Effects of Evaporator Frosting on the Performance of an Air-to-Air Heat Pump. Journal of Energy Resources Technology,” J. Energy Res. Technol., 121(1), pp. 60–65.

[14] Zhang, L., Jiang, Y., Dong, J., Yao, Y., and Deng, S., 2018, “An Experimental Study of Frost Distribution and Growth on Finned Tube Heat Exchangers Used in Air Source Heat Pump Units,” Appl. Therm. Eng., 132, pp. 38–51.

[15] Liu, J., Zhao, B., and Xie, Y. M., 2020, “Analysis of the Influence of Fin Spac- ing on the Performance Fin-Tube Heat Exchanger,” Mach. Des. Manuf., (11), pp. 82–85.

[16] Rao, W., and Lu, Y. J., 2007, “Characteristic Analysis on Air Source Heat Pump With Variable Spacing Fin Heat Exchanger in Frosting Condition,” J. Harbin Inst. Technol., 39(10), pp. 1596– 1600.

[17] Rao, W., and Lu, Y. J., 2005, “Simulation and Analysis for Air Source Heat Pump Variable Finned-Tube Heat Exchangers Under Frosting Con- ditions,” Proceedings of the Annual Conference of Refrigeration and Air Conditioning of China Refrigeration Society, Kunming, Yunnan, China, pp. 161– 166.

[18] Lang, Q. Y., Shen, J., and Yang, N., 2003, “Improvement of Finned Tube Evap- orator Under Frosting Condition,” Refrig., 022(003), pp. 47–51.

[19] Qin, H. J., and Li, W. Z., 2014, “Simulation and Experiment on Performance of Air Cooler With Variable Pitch in Frosting Conditions,” J. Therm. Sci. Eng. Appl., 13(3), pp. 206–212.